Introduction

Almost all mobile devices such cell

phones have battery and battery charger built-in. During product development,

there is a need for battery simulator to properly testing these mobile

devices, especially the charging circuitry. Recent advances in rechargeable battery

technologies such as those lithium-ion and lithium iron phosphate high energy

density batteries are being used in many mobile devices such as cell phones and

tablets. These battery-powered portable devices required thorough bench testing

during the development phase. As will be discussed later, battery simulator is

an important piece of test equipment for lab bench testing.

What is a Battery Simulator?

A battery simulator is an

electronics device that emulates many real battery characteristics. These

characteristics are voltage, power, current, ESR, and more. It provides the

necessary voltage, power, and current to the mobile system like a real battery

does. The mobile device will not know the difference between a real battery and

a simulator. When charged, a battery simulator will sink current; when not

charge, it will sources current to the mobile system load. Battery simulator

can seamlessly transition between source and sink current without glitch even

at high transitional speed. It is a very convenient bench testing tool for test

battery-powered devices and system.

When a real battery is being charged,

its voltage is slowly rise and may take hours to arrive at its final voltage. A

battery simulator on the other hand, its output voltage can easily be

controlled by a knob or a computer program, and can reach the final voltage in

seconds. Battery simulator is ideal for testing battery chargers.

Why Using Battery Simulator

The purpose of a battery simulator is to

replace the battery in a mobile device with an emulated “battery”. Usually a

battery simulator is replacing the battery for testing purpose. The mobile

device operation and performance are generally not impacted by it. It enables

engineers conveniently and thoroughly tests these portable systems both during product

developments and mass production. Below are some examples why battery simulators

are important test equipment.

Charger Testing

Most mobile electronic devices have

built-in charger circuitry that recharges the battery. During product

development and mass production testing, the charger circuit must be thoroughly

tested to ensure its reliability and safely chargers batteries. A typical

battery charging cycle, from dead battery to full, may take up to several hours

complete. If the battery charger is tested with a real battery, it will take

hours. A battery simulator can quickly adjust its output voltage from 0V (dead

battery) to 4.2V (fully charged) in just seconds. It enables test engineers to

quickly test a battery charger. Similarly it may take several days to discharge

a real battery in a mobile device, but a simulator can emulate the battery

being depleted in a matter of seconds. All of the while test engineers can

observe how the system and charger behave and measure the system to make sure

it meets all of the specifications without waiting for hours. Battery simulator

can simulate an overcharged battery or a wrong battery type. If a malfunction

is found in the system, a battery simulator is an indispensable piece of test equipment

for debugging, because engineer can easily simulate the battery voltage from

high to low and back-and-forth to find where the malfunction occurred. Battery

simulator is very important for charger circuit testing.

Battery ESR and Temperature Simulation

Advance battery simulator can even

emulate dynamic battery ESR (electric static resistance). Battery ESR is generally dynamic and frequency dependent. In addition, ESR changes with battery size and capacity, state of charge, battery type, temperature, age, among others. An

advance emulator or simulator can easily change these characteristic to simulate various

type of battery cells and capacity, in addition to simulating battery temperature. An advance simulator can artificially changes the age of that battery, battery

temperature, battery size, just to name a few.

Testing Cell Balancing

Another important application of simulator is to emulate a series-connected battery cells inside a battery pack. Many

medium-power mobile devices employ multiple cells connected in series within a pack. Often time these batteries are lithium-based such as lithium-iron-phosphate (LiFePO4). Common configurations are 2, 3, 4, and 6 cells in

series. Series connecting these batteries increases the system input voltage and

deliver power more efficiently. Due to battery voltage variations from one cell to the

next, not all cells in a pack are at the same voltage. In rear cases,

one or two of the batteries are damaged or defected. When charged a series

connected battery cells, some cells will be over-charged and others

are under charged. Without cell balancing, system design engineers often

intentionally undercharge the battery cells to avoid potential overcharge a

battery cell. Therefore cell balancing is often needed to obtain the

most optimal battery energy as well as keeping the battery pack safe.

Understand Battery Cell Balancing

Battery cell balancing is a process that

ensures each cell in a pack is charged to their optimal capacity. It also

ensures batteries are neither overcharge nor undercharge. This is usually

achieved by using a balancing circuit is to divert charges away from

fully-charged batteries to the uncharged batteries. As shown in Figure 1,

when one of the cells is closer to fully charged, the cell balancing

circuitry diverts some of the charging current away from that cell while maintaining high

charging current to the two undercharged cells. As the battery is approaching

fully-charged, charging current is continued to reduce. The process continues

until all three batteries are full-charged.

Figure 1. Simplified battery cell balancing concept showing the top battery is nearly full and reducing charging current.

Stress Test Cell Balancing Circuitry

The balancing circuitry as well as the

charger itself must be properly tested during product development. To

efficiently test the cell-balancing circuit, one or more battery simulators are

needed. Design engineers can simulate one or more battery is being out of balance

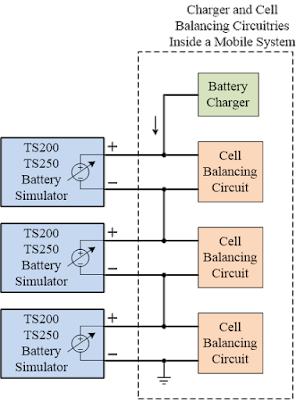

to stress test how the battery cell balancing circuits reacts. As shown in

figure 2, each simulator/emulator can adjust its voltage independently. By doing so, it

is quite easy to adjust each emulated battery voltage to mimic a battery is

either full, undercharged, overcharged, dead-battery, or damaged. Test

engineers can easily simulate any combinations of the above mentioned battery cell conditions (undercharged, overcharged, fully charged, or damaged) to stress

test both the cell balancing and the charger circuitry. In conclusion battery simulators

are ideal for testing battery charger and battery cell balance circuitry.

Figure 2. Three simulators are used to

test the charger and cell balancing circuitries.

How does a Battery Simulator Work?

In a nutshell, a battery simulator is a special power supply that can sink and

source current. A real battery can do the same. This type of power supply is

sometimes called two-quadrant or four-quadrant (if voltage can be negative) power

supply. In the contrary, a typical lab power supply can only source current,

but cannot sink current. Therefore a bench power supply cannot be use as a

simulator. The battery simulator circuit and its ability to sink and source

current is depicted in Figure 3B. A conventional source only power supply is

depicted with a single transistor for sourcing current. A simulator has two

power transistors: one for sourcing and one for sinking current. It can quickly

transitions between sink and source current without any glitch.

How to Use a Battery Simulator

The purpose of a battery simulator is to

replace a real battery for fast and efficiently test battery chargers and mobile

systems. The TS250 and the TS200 are designed to simulate a battery. They

can sink and source current as a real battery does. They can also be used to

simulate battery noise such as ripples and voltage transient for system

testing.

As shown in Figure 4, the TS200/TS50

battery simulator output is connected to a mobile system charger’s battery

terminals. They are taken place of a battery. Use the DC OFFSET knob to adjust

the emulated battery voltage, at the same time monitor the charging current.

Adjust the battery simulator output voltage from low to high and back to

observe the charger behavior.

Figure 4. TS250 Battery simulator and

battery noise generator is used to test chargers

Conclusion

Battery simulator is a very important

equipment for testing mobile devices with a battery charger circuitry. Common

batteries used for today’ portable systems are lithium iron phosphate (LiFePO),

lithium ion (Li+), lithium polymer, nickel metal hydride (NiMH), nickle cadmium

(NiCd), and lead-acid. Most battery simulators can emulate these batteries for

testing battery charger and system. Battery simulator is ideal for both bench

testing during product development and fast testing during mass production.