Battery Emulator Tests Charger and Cell-Balance

Mobile phones need considerable testing during their design

stage to make sure that their batteries and charger circuits operate in the

right way. A battery emulator or sometimes called simulator has the capacity to

supply these kinds of tests which are not easily provided by the use of the

actual batteries.

In order to operate appropriately, battery-powered portable

systems depend on their batteries themselves and the chargers. However, making

use of actual batteries isn't going to allow design engineers to easily do a

complete check of the operation of the system with its battery as well as its

charger. A device that can help remedy this matter for designers is the emulator

that can replace the actual battery throughout testing. This simulator helps

save time and is also crucial to test performance throughout production and

throughout system development.

The types of batteries which are commonly seen in today's

mobile systems are lithium-ion (lithium-ion), lithium-polymer, lithium-iron

phosphate, nickel cadmium (NiCd), nickel metal hydride, and lead-acid. The most

popular kind of battery at the moment is the rechargeable lithium-ion type.

This is because it creates more power for its weight (high energy density).

A battery emulator/simulator provides required power,

current, and voltage to the system being tested with no visible distinction

from the real battery. A full-function simulator is able to easily source and

sink current. Even at high speeds, the switching from sink to source is handled

with no trouble.

A full-feature battery emulator is able to:

- Alter its output to source the needed current and voltage provided to the mobile system load.

- Set its output within seconds unlike a real battery which may demand much longer to arrive at its fully-charged voltage (under the assumption that it was discharged).

- Sink current, which makes it possible for the functioning of the battery charger to be verified.

- Emulate the internal (series) resistance of the battery to measure the response of the system.

- Replicate battery noise to take a look at the system's reaction.

A full-feature battery emulator is really a power supply

that is able to sink and source current. It utilizes a kind of power supply

called 2-quadrant or, if the voltage is negative, four-quadrant. Alternatively,

a regular power supply can source current but lacks the ability to sink

current. The typical source-only power supply employs output transistor that is

designed to source current (Figure 1). The simulator (Figure 2) contains two

power transistors at the output: one that sources and the other that sinks

current. Additionally, it can quickly switch from sink to source current

without creating any issues.

|

Figure 1. A simplified version of the traditional power supply

circuit. It uses a singular output transistor meaning it can only sourcing

current.

|

|

Figure 2. Simplified emulator power supply circuit. It can source/sink

current by employing two output power transistors.

|

Figure 3 represents the equivalent circuit of the TS250

Waveform Amplifier displayed in Figure 4. The TS250 possesses the qualities

required for a battery emulator. It can source and sink current the same way a

realistic battery does. Its DC Offset control modifies the output voltage which

mimics modifications in the battery voltage. Input impedance is typically

either 1kO or 50O, which achieves the minimum amount of noise. TS250 features a

selectable gain is either 20dB or 0dB. Several fault protections are included: over-heating

(thermal), output over-current, input under-voltage, and input over-voltage.

The TS250 is a high current amplifier so it can additionally be utilized to

create battery noise like voltage ripple as well as transient voltage spikes.

The TS250 accepts universal AC input power input from 105VAC to 230VAC and 50/60Hz.

|

Figure 3. Simplified high-Current amplifier circuit use for battery

simulation.

|

|

Figure 4. TS250 Current Amplifier put to use as an emulator. It

features dual LCD displays: One for current and one for voltage.

|

Use Emulator to Test Battery Chargers

The battery emulator or simulator can evaluate the

performance of chargers to make certain they are dependable and are able to

correctly recharge batteries. A battery could require a sizable period of time

to discharge to permit its associated charger to be analyzed; conversely, an

emulator can imitate a drained battery voltage in just a few seconds. A full function

simulator does not need a long wait to test if a charger functions the way it

is supposed to and meets its specs. A battery simulator can replicate an

overcharged battery and can also replicate a wrong battery model type. In the

event of a system not working correctly, an emulator can easily create “battery

voltage” from high-to-low and low-to-high so that the circumstances under which

the failure took place can be found.

A battery simulator is normally used for testing the

operation of the charger within the entire battery voltage (which is from 0

volts to 4.2 volts for li-ion batteries). For instance, the typical operating

voltage for a li-ion battery is 3.0 volts to 4.2 volts, but the voltage can be

from 0V to 3.0 volts if it is mostly depleted. The charger has to be tested to

be certain that it is able to charge a battery which is at any voltage inside a

certain limit. By using a battery emulator, you can imitate the battery at any

voltage by just adjusting the output voltage. Designer can measure the charger

current at the low battery voltage (under 3 volts for a li-ion), normal voltage

(3 volts to ~4.2 volts), and high voltage (over 4.2 volts) to investigate its

full-charged output. For instance, a lithium-ion battery usually utilizes a

constant-current-constant-voltage (CC/CV) charging method. Starting at low

voltage (below 3.0 volts), the battery is trickle charged with a low current

(which is one-tenth of the usual charge current). Between 3.0 volts and ~4.2

volts is the regular fast charge current. When the battery voltage reaches 4.2

volts, it enters a constant-voltage mode in which the voltage is held constant,

at the same time the charger current is slowly reduced. Figure 5 shows a

detailed CC/CV lithium battery charging profile.

|

Figure 5. Current/voltage profile for a Constant Current/ Constant

Voltage (CC/CV) charger.

|

|

Figure 6. TS250 battery simulator is used to confirm the cell-balance

and charger's specs and functions.

|

Like Figure 6 shows, the output of the TS250 battery

emulator is linked to the mobile system's battery connectors. The emulator

takes the spot of the battery pack. To test the charger, change the DC-OFFSET

control to change the simulated battery voltage while taking note of the

charging current. Move the output voltage of the emulator from low to high and

high-to- low to show how the charger is reacting to changes.

Emulate ESR

A simulator can simulate battery’s internal resistance or

equivalent series resistance (ESR). Battery ESR is non-static (dynamic) and

depended on frequency. As demonstrated in Figure 7, ESR is modeled as a

resistor in series with a battery. Additionally, Electric Static Resistance

changes with changes in battery capacity, chemistry, state-of-charge, age,

temperature, and more. An emulator is able to alter these characteristics

without difficulty in order to replicate different types of batteries and

capacities and battery temperatures. The simulator's settings have the

capability to artificially transform the health of a battery with regards to

temperature, size, and various other factors.

|

Figure 7. Battery Electric Static Resistance is emulated with a

resistor in series.

|

Test Cell-Balance Using Battery Simulator

Another fundamental use of battery emulator/simulator is to

emulate a series-connected battery inside a cell pack. Various medium-power

mobile systems utilize several batteries connected in series inside a pack.

These batteries are primarily lithium-ion or lithium-iron-phosphate. Popular

configurations are two-, three-, four-, and six-battery cells in series. Attaching

batteries in series boosts the input voltage of the system and makes it

possible to supply electrical power more efficiently. As a result of variations

in voltage output from one cell to the next, it is possible that most of the

cells within a pack may not be at the exact same voltages. In addition, there

are cases in which one or more of the batteries are damaged or broken. When charging

cells connected in series, it is possible that some of the cells are

undercharged and some battery cells are over-charged. Without the use of cell

balancing, the designer might deliberately under-charge the battery pack to

prevent over-charging any of the batteries. Therefore, cell balancing is

required to achieve the peak battery capacity as well as retaining battery pack

safety.

As displayed in Figure 8, at the time one of the batteries

nears being fully charged, the active cell balance circuit diverts a part of

the charging current away from that specific battery while sustaining a large

current for the two under-charged batteries. As the battery is getting close to

full, the charging current continues to scale back. This method is carried on

until all three batteries are completely charged.

|

Figure 8. When one of the batteries is near being fully charged,

the charging current is adverted through the active cell balance circuit.

|

|

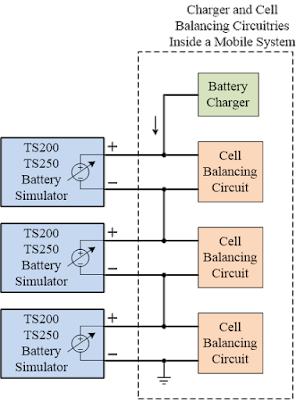

Figure 9. Three simulators are being used to test the charger and

the cell balancing circuitry.

|

The charger, along with the balance circuitry, need to be

carefully evaluated during the entire design stage. To evaluate the cell

balancing circuit needs at least one battery simulator. Design engineers can

replicate a number of cases where that battery is out-of-balance to monitor the

manner in which the cell balancing circuits respond. As depicted by Fig. 9, all

emulator can change its voltage on their own. In this way, it is pretty easy to

change each emulated battery voltage to imitate a cell as either undercharged, depleted,

full, over-charged, or damaged. System engineers are able to very easily

simulate many combinations of these above mentioned battery scenarios (fully

charged, over-charged, under-charged, or defective) to stress test the charger

and also the cell balance circuit.

The TS250 emulator also includes a built-in current monitor.

In case where the simulated cell is over charged (more than 4.2V which usually

shouldn't occur), there should not be any kind of charging current to that specific

cell. Other battery cells should still be charging like normal. If one of the

emulated batteries falls under the safe voltage limit (for example, fewer than

3v), the balance-circuit should either block the charger from commencing rapid

charging (by remaining in trickle charge), or it could stop high charging

current to that battery. The charger and cell-balance circuit behavior is

depended on the charging system design, both hardware and software. There could

be many charging behaviors and outcomes. Every one of the possible behaviors

has to be evaluated.

In conclusion, simulator offers huge efficient ways of

verify portable systems. To help save a lot of time, test engineers can control

the "battery" to any voltage at the changing the control knob. It

will sink and source current much like a real battery would. A number of battery

emulators are often necessary emulate multiple cells for verifying balancing-circuit

along with charger circuit.